Meili Robots Launches Major Update to Fleet Management Platform, Targeting Multi-Level Warehouses

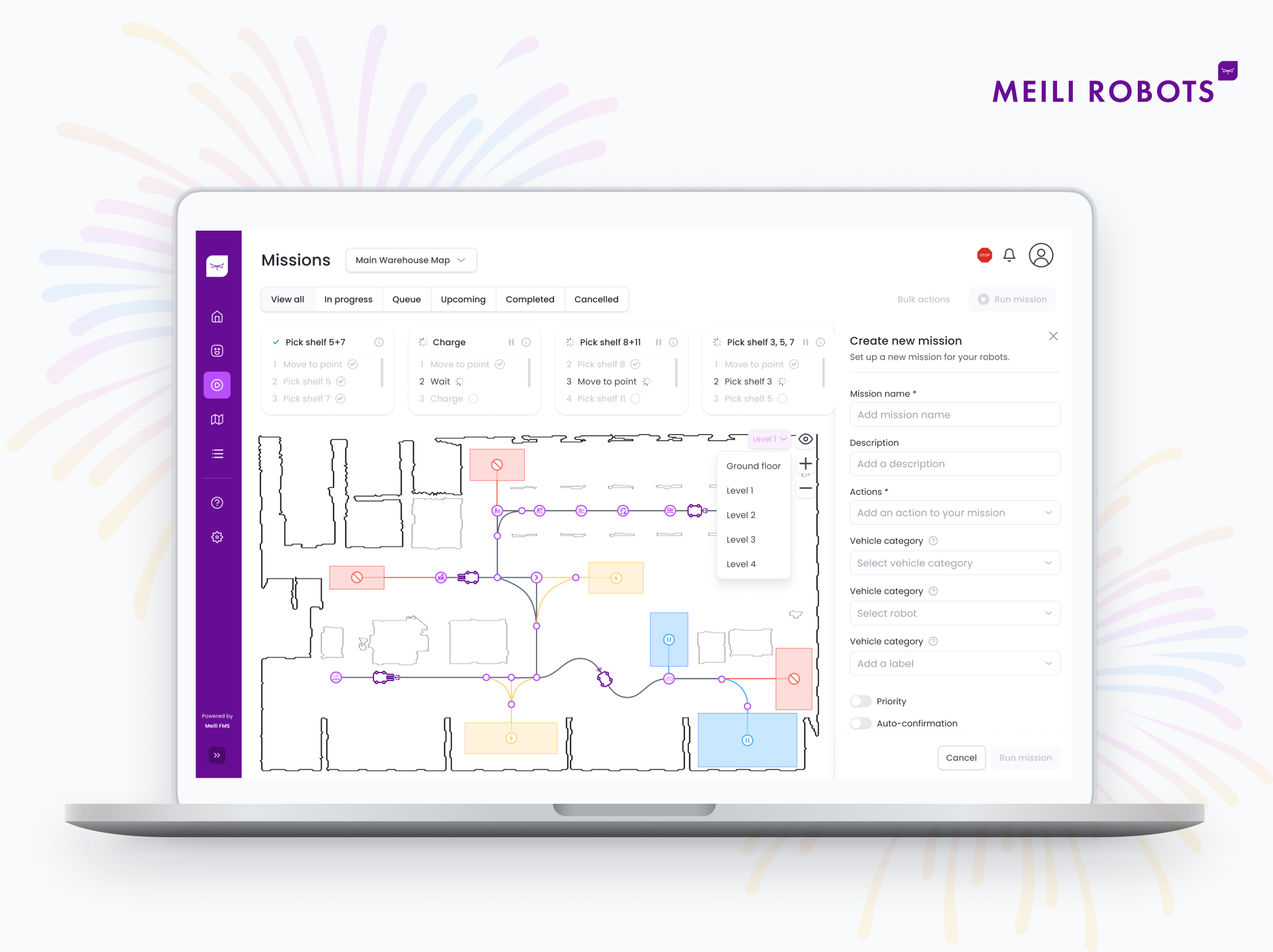

Meili Robots has rolled out its most significant update of the year to its Meili FMS fleet management platform, introducing new multifloor coordination capabilities aimed at customers operating increasingly complex logistics and warehouse environments.

As autonomous mobile robots (AMRs) proliferate in distribution centers and factories, many operators are struggling to manage diverse fleets across large, multi-story facilities. Meili’s latest release, FMS 4.0, is designed to provide a single control layer that can monitor and dispatch robots across entire vertical operations.

A Focus on Vertical Logistics

The headline feature, Multifloor Capabilities, allows operators to track, direct, and optimize robot behavior across several levels of a facility. According to the company, the goal is to eliminate one of the most persistent barriers to scaling AMR deployments: robots that can navigate a warehouse floor, but not the warehouse as a whole.

“The future of robot fleet usage is branching towards multi-story and highly complex use-cases,” said Aldus von der Burg, CEO of Meili Robots. “This release is not just about new features; it’s about providing the robust, scalable intelligence our customers need to thrive in vertical logistics.”

User Interface and Performance Refresh

The update also includes a redesigned dashboard that provides real-time operational insights, allowing warehouse teams to identify bottlenecks and adjust workflows quickly. Improved navigation and workflow design aim to shorten the learning curve for operators — a key selling point as more non-technical warehouse staff interact with automation systems daily.

Other upgrades include:

Advanced Customization options to align the platform with unique workflows and integrate with existing systems.

System-wide performance improvements, supporting larger robot fleets and higher-volume mission planning.

Vendor-Agnostic Integration

Meili Robots positions its platform as a unifying software layer for AMRs from different vendors, addressing an industry challenge as logistics operators increasingly assemble mixed fleets. By remaining vendor-agnostic, the company says it helps customers avoid lock-in and scale automation based on task needs rather than single-supplier limitations.

As more warehouses look to expand vertically to maximize space efficiency, the ability to centrally direct robots across floors is expected to become a core requirement rather than a specialty feature. Meili’s update is a signal that software orchestration — not just robot hardware — is becoming a defining factor in automation strategy.

More information about Meili FMS 4.0 is available at www.meilirobots.com.