Lely Surpasses €1 Billion as Dairy Robotics Demand Grows

Lely’s long-term bet on specialization is paying off. By focusing exclusively on dairy automation, the Dutch robotics company surpassed €1 billion in revenue in 2025, driven by strong milk prices and continued innovation in robotic milking and feeding. But heading into 2026, market volatility and chip supply concerns could test that momentum.

A New Benchmark for Robot Hands: Researchers Launch ManipulationNet

A global team of robotics researchers has launched ManipulationNet, a new infrastructure for benchmarking real-world robot manipulation. By combining standardized physical task kits with a distributed testing platform and centralized verification, the system allows researchers worldwide to compare results, track progress, and measure how close robots are to reliable, real-world deployment.

Tiny Robot Set to Inspect the World’s Most Powerful Particle Accelerator

Engineers from UK Atomic Energy Authority and CERN have developed PipeINEER, a tiny autonomous robot designed to inspect the beamlines of the Large Hadron Collider. The robot navigates ultra-narrow pipes to detect defects, helping maintain the world’s most powerful particle accelerator while reducing costly and complex manual inspections.

Schaeffler Expands Into Humanoid Robotics With New Partnership in China

German motion technology company Schaeffler AG has formed a strategic partnership with China’s Leju Robotics Technology Co., Ltd. to accelerate industrial deployment of humanoid robots. The collaboration will target factory inspection, logistics, and human–robot collaboration, with Schaeffler planning to integrate thousands of humanoids into its global production operations by 2035.

First Belgian Grower Joins Pre-Commercial Trials of Snack Tomato Harvest Robot

Inaho’s snack tomato harvesting robot has entered its final pre-commercial stage, with Belgian grower Olbrechts Tomaten joining 2026 trials. After strong results in the Netherlands, the system now delivers commercial-level performance. Only one trial slot remains as European interest in greenhouse harvesting automation continues to grow.

From Remote Pilots to True Autonomy: Coco Robotics Pushes Sidewalk Delivery Forward

Coco Robotics has unveiled Coco 2, a next-generation delivery robot designed for full autonomy rather than remote human oversight. Trained on millions of real-world miles and powered by advanced edge computing and simulation, Coco 2 aims to scale urban delivery by operating faster, smarter, and more independently.

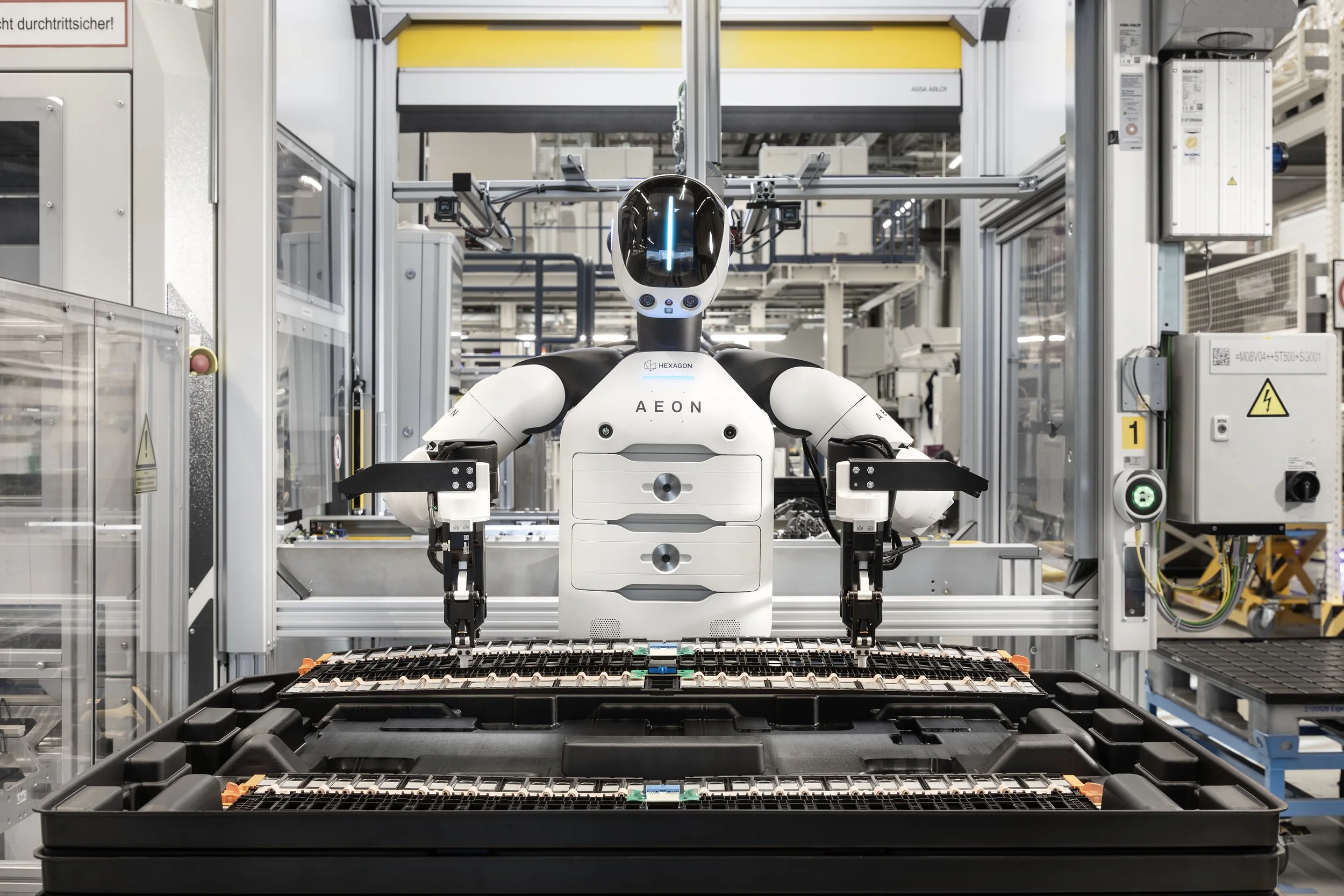

BMW Brings “Physical AI” to Europe with Humanoid Robot Pilot in Leipzig

BMW is bringing “Physical AI” to Europe, launching a humanoid robot pilot at its Leipzig plant after a successful U.S. deployment in Spartanburg. By combining AI agents with real-world robotics, BMW aims to integrate learning-enabled humanoids into battery assembly and automotive production under real industrial conditions.

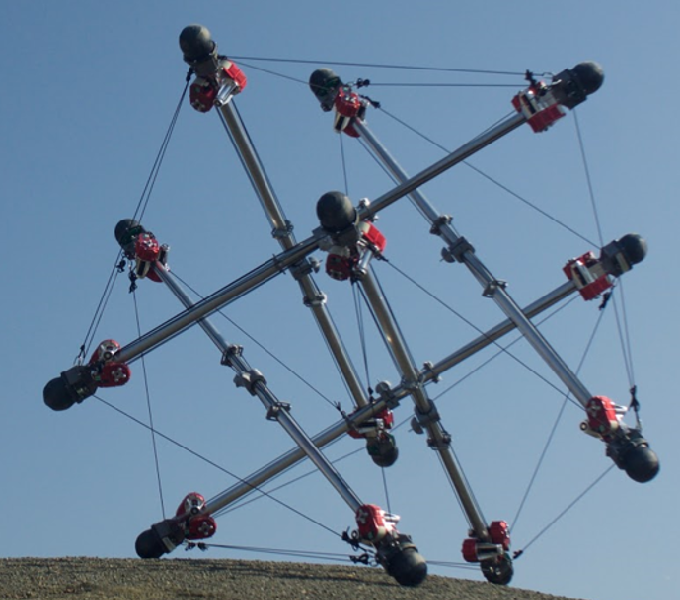

NASA Backs Modular Robotics for Space: HEBI Robotics Wins Phase II SBIR to Advance Space-Ready Actuation

NASA has awarded HEBI Robotics an $850K Phase II SBIR contract to develop modular, space-ready actuation systems capable of operating in harsh orbital environments. The project supports future robotic servicing, assembly, and construction missions while advancing modular robotics platforms that could accelerate both space infrastructure and radiation-hardened applications on Earth.

Rebalancing the Human Body: How a Hip Exoskeleton Could Change Stroke Recovery

Researchers at the University of Utah have developed a lightweight hip exoskeleton that reduces walking energy by nearly 20% for stroke survivors with hemiparesis. By assisting hip movement rather than the ankle, the device improves gait efficiency, reduces strain, and highlights how wearable robotics can restore mobility and independence after neurological injury.

Hyundai’s Firefighting Robots Signal a Shift Toward Robotic First Responders

Hyundai Motor Group has donated four unmanned firefighting robots to South Korea’s National Fire Agency, deploying them in high-risk rescue units. Built on Hyundai Rotem’s HR-Sherpa platform, the robots can withstand extreme heat, operate remotely, and assist with initial fire suppression—marking a shift toward robotic first responders in hazardous environments.

Mantis Robotics and the Emergence of the Fenceless Industrial Robot

Mantis Robotics’ MR-1 marks a potential turning point in industrial automation, achieving safety certification as a fenceless, high-speed robot designed to work alongside humans. By combining Physical AI with advanced safety sensing, the system challenges the long-standing tradeoff between productivity and safety, signaling a new era of collaborative industrial robotics.

Siemens and Partners Launch the UK’s First Fully Customisable AMR Manufacturing Capability

Siemens has partnered with Expert Technologies Group and RMGroup to launch the UK’s first fully customisable autonomous mobile robot (AMR) manufacturing capability. The collaboration aims to deliver flexible, locally supported intralogistics solutions, combining advanced navigation, safety integration, and scalable automation to help UK manufacturers boost productivity and modernise operations.

Milan’s Cutest Disruption: Mirumi, the Robot Bag Charm

At Milan Fashion Week, Yukai Engineering debuts Mirumi—a $149 robot bag charm with baby-inspired eyes and shy movements. Riding the global “kidult” wave fueled by collectibles like Labubu, Mirumi blends fashion, nostalgia, and robotics—proving emotional tech is becoming wearable.

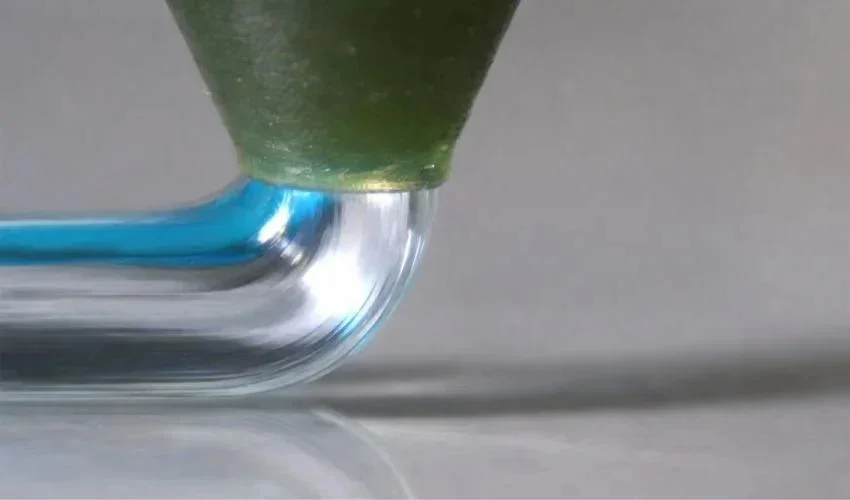

Harvard University Engineers 3D Print Soft Robots That Bend on Command

Harvard researchers have developed a new 3D printing method that enables soft robots with built-in shape-morphing capabilities. Using rotational multimaterial printing, engineers create flexible structures with programmable air channels that bend predictably, simplifying fabrication and opening new possibilities for surgical tools, assistive devices, and adaptive robotic systems across healthcare and industry.

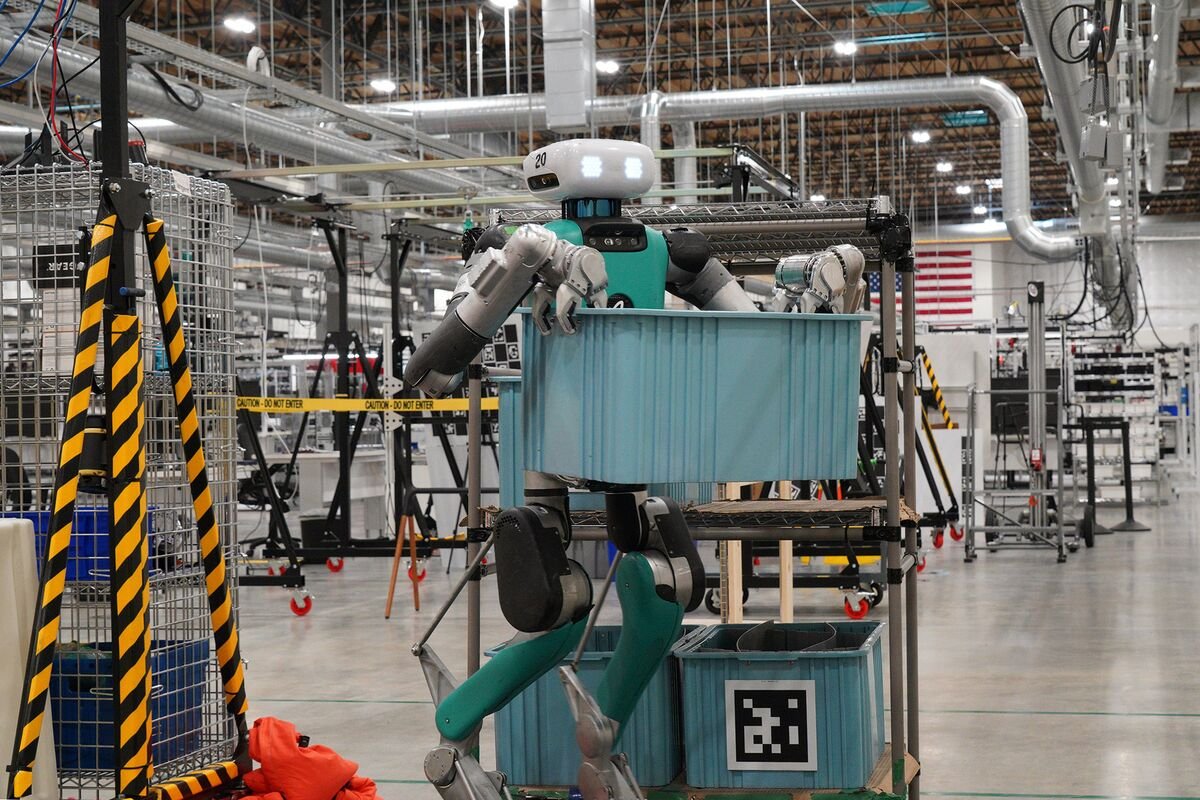

Toyota Turns to Humanoids: Agility Robotics’ Digit Moves Into Automotive Manufacturing

Agility Robotics’ humanoid robot Digit is moving into commercial automotive manufacturing as Toyota Motor Manufacturing Canada plans deployment following a successful pilot. Designed to support logistics and repetitive tasks, Digit reflects growing industry interest in humanoids as flexible automation tools aimed at improving efficiency, safety, and workforce augmentation in modern production environments.

HII and Path Robotics Explore Physical AI Welding for Shipbuilding Automation

HII and Path Robotics have signed an agreement to explore using physical AI-driven welding in shipbuilding, aiming to boost production and augment skilled labor. By integrating adaptive perception and real-time decision-making into industrial robots, the partnership reflects a growing push to apply physical AI to complex, high-variability manufacturing environments like naval shipyards.

Jevons Robotics and Newmont Australia Expand Automation into Highwall Mining

Jevons Robotics has partnered with Newmont Australia to deploy an automated pre-split loading robot designed for highwall mining environments. Built on the ARTEV1000 platform, the battery-electric system aims to reduce human exposure in hazardous zones while maintaining consistent blast preparation, highlighting mining’s growing adoption of safety-focused robotic automation solutions.

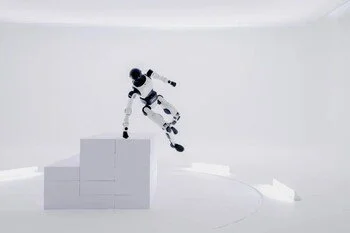

X-Humanoid Launches Embodied Tien Kung 3.0

X-Humanoid has launched Embodied Tien Kung 3.0, a full-size humanoid robot built for practical deployment and open development. Powered by the Wise KaiWu embodied AI platform, the system emphasizes autonomy, interoperability, and high-dynamic motion control, signaling China’s continued push toward scalable, developer-friendly humanoid robotics ecosystems designed for real-world applications.

Sitegeist Raises €4M to Bring AI Robotics to Europe’s Aging Infrastructure

Munich-based startup Sitegeist has raised €4 million to scale AI-powered robots designed for concrete renovation. Targeting Europe’s growing infrastructure repair backlog, its modular systems automate hazardous, labor-intensive tasks directly on existing structures. The approach highlights a shift toward purpose-built robotics addressing skilled labor shortages and complex real-world construction environments.

Agovor Raises AU$3 Million to Advance Autonomous Horticulture Robotics

Agovor has raised AU$3 million to accelerate development of its autonomous horticulture robots, combining electric eTractors with smart attachments designed for orchards, vineyards, and specialty crops. Early deployments show significant cost savings and sustainability gains, highlighting growing momentum behind practical, task-focused robotics solutions addressing labor shortages and efficiency challenges in agriculture.