Toyota Turns to Humanoids: Agility Robotics’ Digit Moves Into Automotive Manufacturing

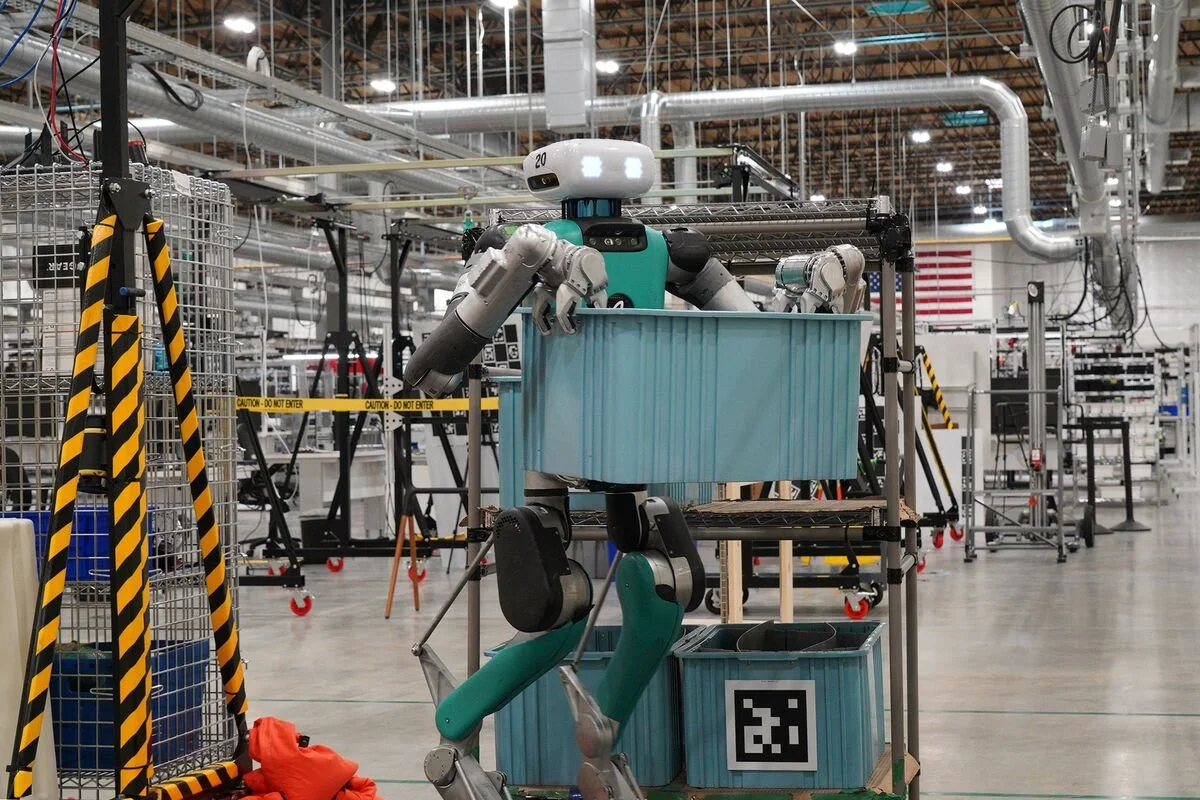

The humanoid robotics sector took another meaningful step toward commercial reality this week as Agility Robotics announced a commercial agreement with Toyota Motor Manufacturing Canada (TMMC), marking the planned deployment of its general-purpose robot, Digit®, into automotive production environments.

Following a successful pilot program, Toyota’s Canadian manufacturing division intends to use Digit to support employees across manufacturing, supply chain, and logistics operations — a move that reflects growing industry interest in humanoid robots as flexible automation tools.

From Pilot to Production

Toyota Motor Manufacturing Canada, one of Toyota’s largest manufacturing operations outside Japan, has long been associated with continuous improvement and advanced manufacturing practices. The decision to move forward with Digit suggests that humanoid robots are beginning to transition from experimental deployments toward operational roles within high-volume industrial settings.

“After evaluating a number of robots, we are excited to deploy Digit to improve the team member experience and further increase operational efficiency,” said Tim Hollander, President of TMMC.

The deployment follows broader trends in the automotive industry, where manufacturers are exploring new forms of automation to address labor shortages, improve ergonomics, and maintain productivity in increasingly complex production environments.

Why Humanoids — and Why Now?

Unlike traditional industrial robots, which are typically designed for highly specific tasks within fixed workflows, Digit is positioned as a general-purpose system capable of adapting to multiple logistics and manufacturing roles.

Agility Robotics describes Digit as a human-centric platform designed to work alongside people without requiring extensive factory redesigns — a critical factor for manufacturers seeking incremental automation without costly infrastructure changes.

Initial use cases are expected to focus on repetitive or physically demanding tasks common on automotive production lines, with the goal of reducing strain and enhancing safety while allowing human workers to focus on higher-value activities.

Toyota and Agility Robotics plan to continue exploring additional applications where robotics and AI can augment production operations, suggesting that the current deployment may represent only the beginning of a broader automation strategy.

Scaling the Humanoid Workforce

Toyota joins a growing list of major companies deploying Agility’s robots, including GXO, Schaeffler, and Amazon. These partnerships indicate increasing confidence among Fortune 500 firms that humanoid form factors may provide new flexibility in environments originally designed for human workers.

Agility CEO Peggy Johnson emphasized the collaborative vision behind the deployment, highlighting the company’s goal of delivering “cooperatively safe” humanoid robots capable of working directly alongside human teams.

Alongside Digit, Agility offers Agility Arc, a cloud automation platform designed to manage fleets of robots — a sign that humanoid deployments are shifting from single-machine demonstrations toward scalable operational systems.

The Bigger Picture for Automotive Manufacturing

The automotive sector has historically been a proving ground for industrial automation, from early robotic welding lines to advanced digital manufacturing systems. The introduction of humanoid robots represents the next phase of that evolution — one focused less on replacing traditional automation and more on filling gaps where flexibility, mobility, and adaptability are required.

As global manufacturers grapple with workforce constraints and rising complexity, the appeal of robots that can integrate into existing workflows without extensive retrofitting is growing.

Whether humanoids ultimately become a standard feature on production floors remains an open question. But Toyota’s decision to move from pilot to commercial deployment suggests that the industry is beginning to test that future in earnest.