HII and Path Robotics Explore Physical AI Welding for Shipbuilding Automation

Huntington Ingalls Industries (HII) and Path Robotics have signed a memorandum of understanding (MOU) to explore the integration of physical AI-driven welding into U.S. shipbuilding operations, signaling a growing convergence between advanced robotics and national industrial priorities.

The collaboration will examine how Path Robotics’ adaptive welding technology could support increased shipbuilding throughput while augmenting the human workforce — a key challenge as naval demand rises and skilled labor shortages continue to impact heavy manufacturing sectors.

Physical AI Meets Maritime Production

Under the agreement, the companies plan to evaluate opportunities across three primary areas:

Development of autonomous shipbuilding capabilities

Workforce training to extend and support automation

Creation of intellectual property frameworks for physical AI-enabled welding systems

Additionally, the partnership includes research and development efforts aimed at integrating Path’s physical AI models with existing shipbuilding technologies and workflows.

Eric Chewning, HII’s executive vice president of maritime systems and corporate strategy, emphasized the operational context driving the collaboration.

“We are excited to partner with Path Robotics to incorporate their state-of-the-art physical AI models to further augment our workforce and speed up U.S. Navy manned and unmanned shipbuilding production,” he said. HII reported a 14% increase in shipbuilding throughput in 2025 and is targeting an additional 15% growth in 2026.

Tackling One of Automation’s Hardest Problems

Welding remains one of the most technically challenging processes to automate, particularly in environments like shipyards where variability is the norm rather than the exception. Shipbuilding involves large-scale components, inconsistent geometries, dynamic environmental conditions, and significant human collaboration — factors that have historically limited the effectiveness of traditional robotic automation.

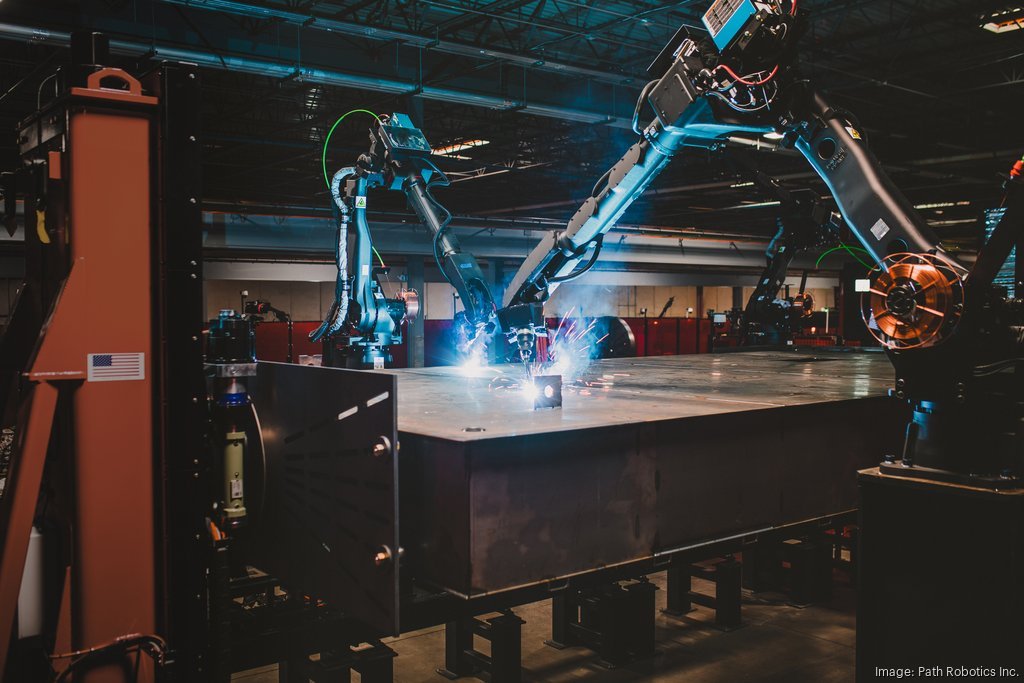

Path Robotics’ physical AI platform, including its Obsidian welding model, seeks to address these challenges by combining sensing, vision systems, and real-time decision-making capabilities. Rather than relying solely on pre-programmed paths, the system enables industrial robot arms to perceive and adapt to real-world conditions as they occur.

“Welding is one of the hardest processes to automate in any industry, and shipbuilding is no exception,” said Path Robotics CEO Andy Lonsberry. “Path’s physical AI is purpose-built for that challenge — seeing, understanding, and adapting to real-world conditions in real time.”

A Broader Industrial Signal

Beyond the immediate application, the partnership reflects a broader trend toward applying physical AI to complex industrial workflows where variability has historically prevented automation at scale. As defense manufacturing faces increased pressure to deliver faster and more efficiently, adaptive robotics systems may play an expanding role in bridging productivity gaps without replacing skilled workers outright.

The agreement also highlights a shift from traditional robotics deployment toward integrated autonomy strategies that combine workforce training, technology development, and intellectual property frameworks.

If successful, the collaboration could represent a significant step toward autonomous shipbuilding capabilities — not as a fully lights-out process, but as a human-centered system where physical AI extends the reach and effectiveness of skilled labor in one of manufacturing’s most demanding environments.