New Study Defines the Skills Workers Need to Collaborate With Robots on Construction Sites

The construction industry is under growing pressure. Chronic labor shortages, persistent safety risks, and decades of stagnant productivity have left contractors searching for new ways to build faster, safer, and more efficiently. Robotics has long been seen as part of the solution—but real-world construction sites remain too complex and unpredictable for full automation.

Instead, researchers say the future of construction robotics lies in human–robot collaboration, where machines handle repetitive, hazardous, or precision tasks while humans provide judgment, adaptability, and oversight. Yet adoption of robotics in construction has been slower than expected, hindered by limited training pathways, workforce resistance, and a lack of clarity around what workers actually need to know to work safely and effectively alongside robots.

A new study from researchers at Virginia Tech and the University of Illinois Urbana-Champaign aims to address that gap. Published on June 5, 2025, in Frontiers of Engineering Management, the research presents the first expert-informed competency framework specifically designed for human–robot collaboration in construction.

Moving Beyond Technology Alone

While robotic systems are increasingly capable of tasks such as surveying, inspection, material handling, and prefabrication, the researchers argue that technology alone is not enough to transform the industry. Effective collaboration depends on workers who understand how robots operate, how to interact with them safely, and how to adapt when conditions change on dynamic job sites.

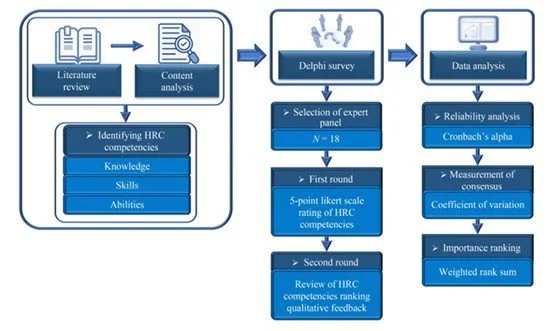

To identify those requirements, the research team conducted a two-round Delphi survey with experienced construction professionals. The structured process allowed experts to evaluate and refine a broad list of competencies until consensus was reached on what matters most in practice.

Before launching the survey, the researchers performed an extensive literature review and content analysis covering construction robotics, safety standards, human–robot interfaces, sensing technologies, and task-planning systems. From this groundwork, they identified an initial set of competencies, organized into 20 knowledge areas, 10 skills, and 12 abilities.

What Construction Workers Need to Know

Through the Delphi process, experts identified several high-priority knowledge domains as essential for human–robot collaboration. These include understanding robotic anatomy and system specifications, knowing where and how construction robots are best applied, and having familiarity with sensing and perception technologies that allow robots to navigate complex environments.

Equally important were knowledge of human–robot interfaces, robotic control systems, and relevant safety standards—areas that directly affect how workers supervise, communicate with, and intervene in robotic operations on site.

On the skills side, experts emphasized task planning, technical proficiency, and programming capabilities, alongside safety management and effective communication during human–robot interaction. The ability to work with data analytics and machine learning tools also emerged as increasingly important as construction robotics becomes more data-driven.

Perhaps most notably, the study highlighted a set of core abilities that extend beyond technical training. Safety awareness, continuous learning, problem-solving, adaptability, critical thinking, and spatial awareness were all ranked as essential. These attributes reflect the reality of construction sites, where conditions change rapidly and workers must constantly assess risk and adjust workflows.

A Framework for Training and Policy

By synthesizing these findings, the researchers developed a unified competency framework tailored specifically to construction environments. The framework underscores the need for cross-disciplinary training that blends engineering knowledge, construction expertise, and human factors.

According to the authors, the framework is designed to serve multiple audiences. Educational institutions can use it to modernize engineering and construction management curricula. Employers can apply it to design targeted reskilling and upskilling programs that improve safety and operational performance. Policymakers and industry bodies may also use the framework as a foundation for developing standardized qualifications and certification pathways for human–robot collaboration roles.

“Robots are reshaping how construction work is performed, but technology alone is insufficient,” the authors noted. “The success of human–robot collaboration depends on preparing workers who can safely supervise, communicate, and adapt alongside robotic systems.”

They emphasized that the competencies identified span technical, cognitive, and behavioral dimensions, reflecting the realities of real-world construction settings rather than idealized automation scenarios.

Preparing for a Robot-Enabled Construction Future

As robotics expands across construction activities—from inspection and surveying to prefabrication and material handling—the need for a robot-ready workforce will only grow. Without clear competency standards, companies risk underutilizing expensive technologies or introducing new safety risks through poor integration.

The researchers argue that aligning workforce development with clearly defined competencies could accelerate adoption, reduce resistance, and help unlock the productivity and safety gains robotics promises.

In an industry where margins are thin and risks are high, the study offers a practical roadmap: not just for deploying robots, but for preparing the people who will work alongside them.